Monday, April 27, 2009

No-wrap heels video

Wednesday, April 22, 2009

International CSM Directory

Go here and fill out her form.

Thursday, April 16, 2009

Cylinder Diagrams

Here's the one found in the AK book:

Here's the LeGare figure:

Here's the LeGare figure: There are two differences in the sketches.

There are two differences in the sketches.- The LeGare shows to pull more needles out of work for the toes.

- The LeGare shows to work the toe on the back of the cylinder. The only problem I see with doing that is that you get your seam on the bottom of the foot rather than on the top.

The other nice thing about these diagrams is that they show you where the sweet spot is located to hang your heel weights. Look inside the circle near the bottom. You will see a small "a" and "b". They're shown to be placed between needles the second and third needles on either side of the heel/toe. For what it's worth, I like to put another heel weight between these two points.

Tuesday, April 14, 2009

Dropped Stitches: Part 1 - Short Runs

- Part 1 - Short Runs (this post)

- Part 2 - Long Runs

- Part 3 - Dropped rib stitches

- Part 4 - Dropped stitches while knitting heels/toes

- Part 5 - Multiple Dropped stitches

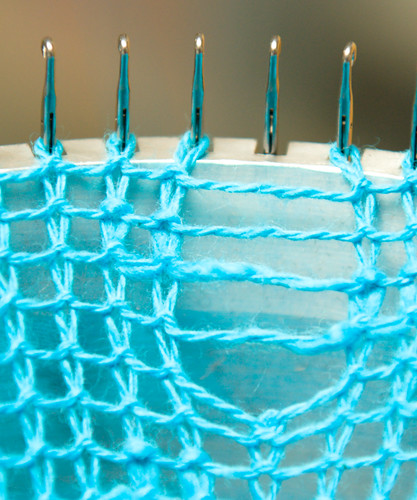

This post is Part 1, and covers short runs from a single dropped stitch (ideally, what you get when you catch them quickly). I apologize in advance for my choice of yarn - I was looking for something easy to see that wasn't too bright for the camera, and what I found in my stash was this blue cotton slub (it's labeled as 3.5/1 weight, which is "about" fingering weight.. maybe a little lighter since it's cotton). Not the ideal CSM yarn by any means, so if it doesn't look like anything you're using, that's why.

A sample of what kind of drop I'm referring to - in plain knitting, a single stitch is dropped, and the run created is at most 4 or 5 rows long (sample shown is 4 rows).

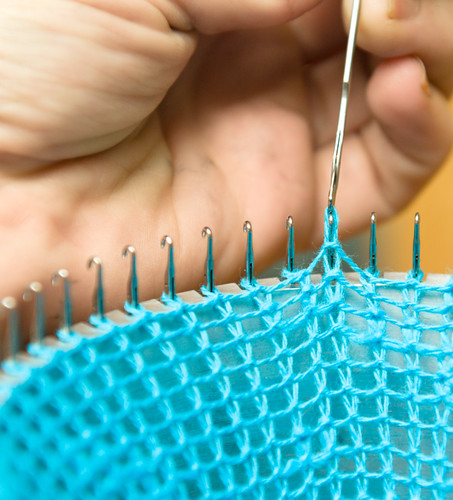

Stopping the Run

First, before doing anything else, REMOVE the weights on your machine - this helps keep the run from extending further. Then, using a spare needle, run the needle under the yarn from the top of the cylinder, and hook into the stitch a row or two below the run (in this photo, I've hooked the stitch 2 rows below). This stops the run, and unlike trying to catch the stitch peeking out at at the end of the run, usually won't cause the run to unravel further. Using your fingers or a pick, gently pull out the stitch or two above where you've caught your needle so you can begin latching the stitches back up.

How To: Remember Cylinder Tension

To remember how to adjust your cylinder tension:

* higher-tighter, lower-looser *

Monday, April 13, 2009

Books: Knock Your Socks Off of Your Circular Sock Machine

Christine Smith wrote a book and has self published. It's available here. The first 15 pages are available for a free preview.

Here's a quick screenshot of her table of contents.

Wednesday, April 8, 2009

Troubleshooting: Needle's won't grab yarn to knit

So, lets try to trouble shoot this.

So, lets try to trouble shoot this.There's knitting on the machine, so the machine is knitting.

Whenever this happens to me, there's one of two things wrong:

- The tension is too tight - adjust the tension screw down to loosen up the knitting. By loosening the tension, the weights should bring the loops down to where they're evenly distributed.

- The weight has hit the ground or is hung up somewhere - the fabric behind is not being pulled down uniformly.

Wednesday, March 11, 2009

Troubleshooting: Needles aren't engaging when doing short rows.

She's having difficulty doing the heels/toes as her needles won't engage after she's pulled the needles out of work and changes direction to do short rows.

She thoughtfully provided photos.

First photo shows where she stops and changes direction.

First of all, Kathy needed to keep cranking until all her needles that are in work are all level. What she's doing here is not allowing the second cam to drop down.

First of all, Kathy needed to keep cranking until all her needles that are in work are all level. What she's doing here is not allowing the second cam to drop down.Remember, this is the path the needle takes while making a loop:

What's happening is Kathy isn't cranking far enough for the needles to clear cam D6 where it's passing under it. Her first couple of needles are still in the V cam. In the next photo, she's changed direction and the needles aren't being lifted. The cam is floating along the tops of the needles.

What's happening is Kathy isn't cranking far enough for the needles to clear cam D6 where it's passing under it. Her first couple of needles are still in the V cam. In the next photo, she's changed direction and the needles aren't being lifted. The cam is floating along the tops of the needles.

If you look at the inside of her machine, you can even see where the needles travel. Look at the clean marks.

Hope that clears it up, Kathy.

Monday, March 9, 2009

Silicone Caulking

If you have an older CSM buckle that is not holding your socks well, dab some silicone caulking on the area where the buckle is in contact with the sock. Should be holding socks back in no time.

The other thing to do is to use it for non-slip socks. While applying the caulk, make sure you get the caulk down into the stitches so little fingers can't peel it off. Just make sure you don't get the toes or heels if these socks are supposed to be able to slip into shoes easily.

Supposed to be good for felted slippers, too.

Tuesday, February 3, 2009

2009 CSMSA Convention

FWIW, it's June 8th - 11th, 2009

Wednesday, January 14, 2009

Did you know?

Tuesday, January 6, 2009

Cone Sock Yarn Sources

From eirual :

Webs - also sells cones of sock yarn, they are not nearly as nice and squishy as Wool2Dye4’s but - they are less expensive. $15 a lb plus shipping (if you order 4 lbs it’s $12 a lb). I find that the color is more cream, the spin is a bit loose.

Bartlett Yarns - lovely cones of sport weight yarn. I find that you really want to use a bit of woolly nylon with this to give the sock a little body. Very easy to knit, I use it to make socks on my 72 needle cylinder with no problems.

Sylvia’s Threads - Best price I have found for woolly nylon.

From sarahspins:

Lion Brand - 100% wool

I should add that one of my current favorite CSM yarns is Treadsoft from Henry’s Attic. The easiest way to buy it retail is likely from Catnip Yarns (just email them - very nice company and super easy to work with). Treadsoft is a smooth 2-ply superwash with a tight twist, it’s not only easy to knit with (it’s a 2/8 yarn, unlike most of the 2-ply sock yarns that are 2/6 and IMO a little on the heavy side), but it wears very well too.

If you have any more sources, please contact me so I can add it to this list.

Saturday, January 3, 2009

CSM Teachers

a variety of machines.

wollon@comcast.net

410 734-7980

Gregory Dodge Wollon

Havre de Grace, Maryland

Donna Peters

http://www.countryrain.com/

Maureen Newell

creatne2@yahoo.com,

11 High Street Fairfield, Maine 04937

207-453-7708

Roxana Baechle

Coleman, Michigan

Baechler@mindnet.org

989-205-7476 and 989-465-1526.

Eric Wolff

Pinckney, MI USA

fine knitted items of all sorts

sock machine sales, maintenance & repairs

ewolff1516@yahoo.com

Barbara Clorite-Ventura

eastern MA

bclorite@verizon.net

Judy Scheuneman

Knitewe1@intouchmi.com

Specializes in new knitters/ribbers

carries small parts for sale

Wisconsin and Michigan areas

Maureen Patterson

Roseburg, Oregon

mpat777@charter.net

Stephanie DeVoe

Plum Cottage Crafts

Frederick, MD

sdevoe@comcast.net

www.plumcottage-crafts.com

Katy Abbas

New Hampton, Iowa (NE) 1945 Kenwood Ave. Variety of CSM's

Sales, repair, restoration, parts, new parts machined and

lessons katy@thelegacyfarm.com 641 394 3627

Laura Schickli

http://handwerkstextiles.com

teach 3 classes as well as give private instruction based on the customers needs. classes are:

Basic CSM set up and Machine Adjsutment, Knit a sock, Fancy Sock Tops

hand dyed sock yarns, and needles laura@handwerkstextiles.com San Francisco Bay Area, CA. BayAreaCSMers group

Susan Forsyth

http://www.woolcombs.com/

+1 (604) 288-9811

susanf@rocketmail.com

Located in Mission, British Columbia, Canada

classes in all levels. Willing to travel

new knitters welcome.

CSM Repairs and maintenance.

classes also in spinning, felting, dyeing.

wide variety of small parts: - lifters, picks, crescents(wood and

metal), heel hooks, long handled stitch catchers.

Melanie Wilson

Leicestershire UK

Willing to help get people going on sock machines. Also Dyeing instruction.

0116 2604442 or socks@dragonflight.co.uk